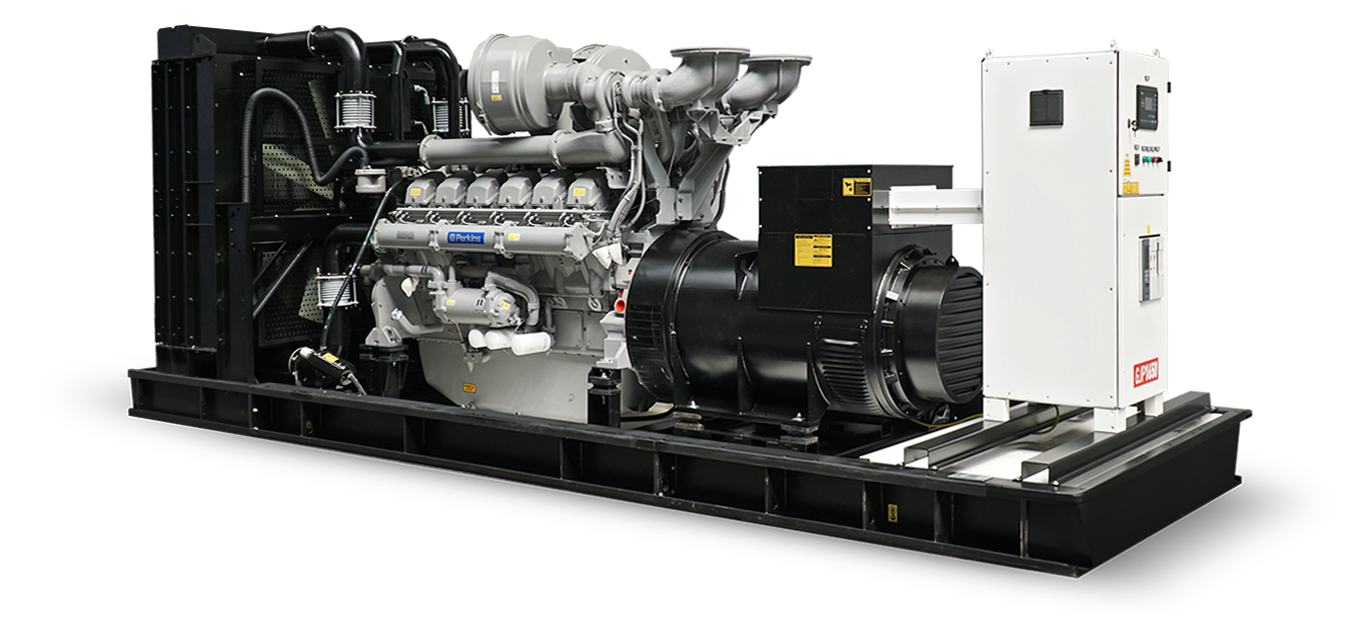

Generators are machines that play a critical role in providing uninterrupted electrical power. The need for generators is increasing, especially in locations where electricity supply is unsustainable, such as industrial facilities, hospitals, construction sites, and large event venues. Technical support services such as regular maintenance, filter replacement, and component inspections are crucial for the smooth operation of a generator. Corporate generator manufacturers, sales, and rental companies often also offer maintenance and repair services. As Güçbir Generator, we hold a significant position among these companies. We provide professional services in repair, maintenance, and sales.

Generator set maintenance isn’t just about changing the engine oil or filters. It also encompasses technical details such as inspecting the fuel system, checking the cooling system, testing electronics, and evaluating battery performance. Diesel, gasoline, and marine generators, in particular, require distinct maintenance protocols due to their different engine designs and operating principles. In this article, we’ll cover the basic concepts of generator maintenance, key points to consider during the maintenance process, and pricing criteria. We’ll also examine the key differences in maintenance between diesel, gasoline, and marine generators in detail. All this information will guide you to ensure the most efficient and safe operation of generators, which are crucial for providing uninterrupted power.

How Should Generator Maintenance Be Done?

The first step in generator maintenance is to accurately follow the periodic maintenance intervals specified by the manufacturer. During this period, the generator engine oil level and quality should be checked, and the generator engine oil should be changed when necessary. Consumables such as the generator fuel filter and generator air filter should then be inspected and replaced immediately if any blockages or deformations are detected. Contamination in generator engine filters can reduce generator performance, increase fuel consumption, and lead to serious long-term malfunctions.

Electrical inspections are also an important part of generator maintenance. The generator’s alternator, rotor, and stator components should be tested, and cable connections should be checked for looseness or oxidation. The battery plays a critical role in the generator’s initial start-up; therefore, its state of charge and electrolyte level should be measured at regular intervals. A voltage drop in the battery, in particular, poses a risk of the generator failing to start.

Another important issue is ensuring proper cooling system maintenance. Radiator and coolant levels in diesel generators should be checked regularly to prevent potential leaks or blockages. Finally, the generator exhaust system should be inspected to identify carbon buildup and leaks. Having these steps performed by experts ensures safe and uninterrupted operation of the generator. As Güçbir Generator, we offer maintenance services. You can access our maintenance services by using our Güçbir Generator service .

How Are Generator Maintenance Prices Determined?

The most important factor affecting generator maintenance costs is the generator type and capacity. Parts costs and maintenance requirements can vary between diesel generator sets, gasoline generators, or marine generators. For example, because high-capacity industrial diesel generators require more filters, oil, and spare parts, maintenance costs can be higher than smaller generators. Furthermore, the generator’s manufacturer’s brand plays a significant role in spare parts availability. Maintenance and repair costs for commonly used generator engine brands are generally more predictable due to the ease of parts procurement.

The frequency and scope of maintenance is another important factor influencing pricing. Some businesses opt for comprehensive “annual maintenance” packages to ensure longer, trouble-free operation of their generators, while others may opt for periodic generator maintenance or a breakdown-based generator maintenance service. The difference between these two approaches is reflected in the pricing. Generator maintenance agreements that include 24/7 technical support, especially in critical applications (hospitals, data centers, etc.), can increase costs, but they also minimize the risk of potential failures and significantly reduce operational losses.

Finally, geographic location and transportation costs can also be determining factors in pricing. The cost of transportation for the maintenance team to the site, labor costs, and additional logistics expenses are among the factors that affect the total generator maintenance cost. Therefore, before signing a generator maintenance contract, it’s crucial to clarify your business’s needs and obtain a detailed quote to make the best decision. Contact Güçbir Generator to learn about maintenance prices and take advantage of this service.

Diesel Generator Maintenance

Diesel generators, thanks to their durability and high torque capacity, are preferred in many applications, from industrial sites to large-scale projects. Fuel system cleaning and filter changes are crucial in the maintenance of diesel generators of various brands and models. Undesirable substances in diesel fuel, such as sulfur, sediment, and water, can clog fuel pumps and injectors. Therefore, diesel generator fuel tanks should be cleaned regularly, and generator engine fuel filters should be replaced.

Additionally, the condition of the diesel generator engine air filter directly affects engine performance. A clogged air filter reduces the combustion quality of the generator engine and increases fuel consumption. Because radiator fluid ensures the generator engine operates within the appropriate temperature range, maintenance of the cooling system should also be maintained regularly. Using antifreeze and protective additives, generally recommended by the manufacturer, prevents corrosion and extends generator life. Battery maintenance in diesel generators should also be prioritized to prevent voltage drops or charging problems. Finally, routine inspections of engine and exhaust components are critical to performance and safety.

Gasoline Generator Maintenance

Gasoline generators are typically distinguished by their quick solutions to short-term power outages and their easy-to-carry design. However, regular maintenance is crucial to maintain these advantages. First and foremost, ensure that the gasoline used is fresh. Long-term or poor-quality fuel can cause engine starting difficulties and loss of performance. Therefore, tank cleaning should not be neglected, and old fuel should be completely drained and replaced periodically.

In gasoline generators, the carburetor is a critical component that ensures the proper mixing of fuel with air. Sludge or resin-like residue that may accumulate in the carburetor over time negatively impacts engine speed. Therefore, the carburetor should be cleaned regularly, preferably by professional means. Additionally, spark plugs should be frequently inspected for wear and debris and replaced if necessary. For efficient engine operation, the oil level and quality should be checked periodically and replaced with oils that meet the manufacturer’s recommendations. All these maintenance steps contribute to the long-lasting, safe, and high-performance operation of the gasoline generator. You can receive gasoline generator maintenance services from our company.

Marine Generator Maintenance

Marine generators are a specialized type of generator designed to cope with the harsh conditions of the marine environment. Used on ships, yachts, or offshore platforms, these generators require extra care in their maintenance due to high humidity and salinity. First and foremost, all metal components of the generator should be regularly inspected and, if necessary, protective coatings applied to minimize the risk of corrosion. Rust formation at connection points can weaken cable contacts and cause electrical faults.

The cooling system is critical for marine generators. In cooling circuits using seawater, salt and limescale can clog the radiator or heat exchanger surfaces. Therefore, water circuits should be cleaned periodically, and any filters should be replaced. Because fuel quality can fluctuate in the marine environment, regular fuel tank cleaning and filter changes are crucial. Furthermore, stainless steel or protective chemicals should be used to protect the exhaust system from saltwater. Battery connections and power cables should also be periodically inspected for oxidation, and all necessary precautions should be implemented to ensure a long-lasting and reliable energy source. Marine generator maintenance is crucial for the longevity of the equipment.