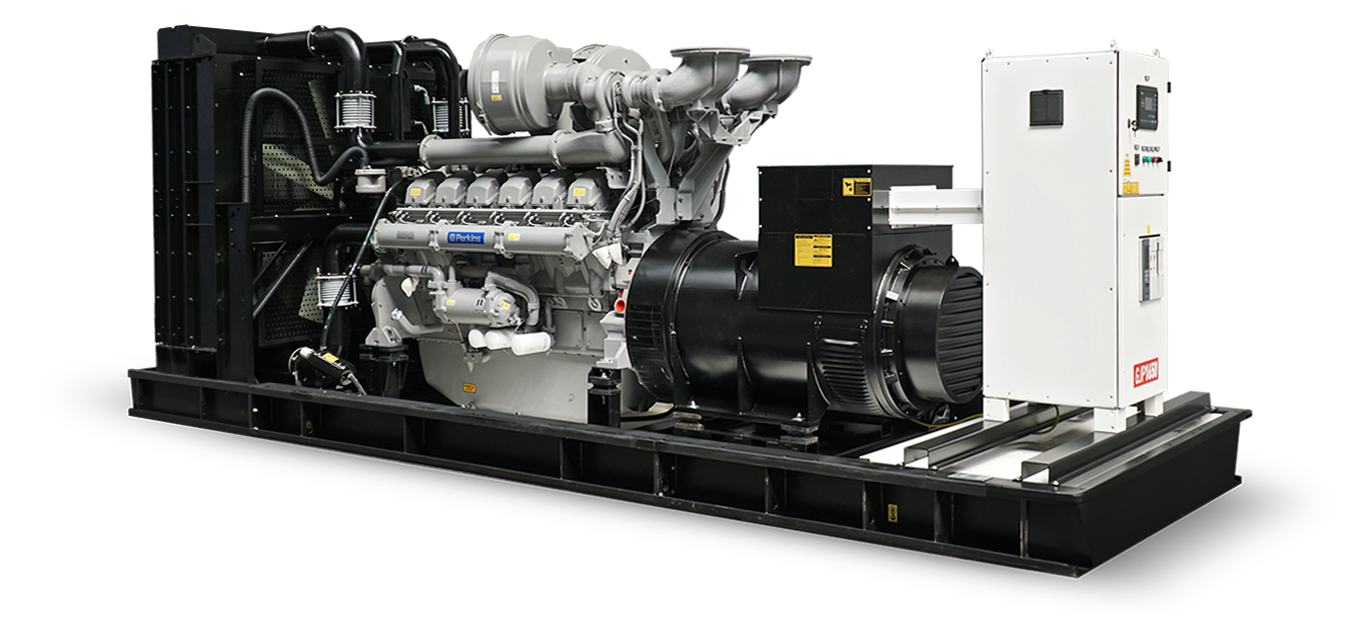

Points to Consider When Buying a Second Hand Generator

Buying second-hand, lightly used generators provides advantages in many ways. Buying a second-hand generator is the most cost-effective way of acquiring high quality generators, which is why many companies have a second-hand sales department. However, there are several considerations that should be taken into account before making the purchase, which is the main purpose of this article: The first consideration is to select a generator with the power to meet your specific power requirement. For more detailed information on this, see our article on sizing the generator. Once you have determined the power you need, it is time to examine other factors.

Some key considerations when purchasing a used generator (diesel, natural gas, electric propane, gas, etc.) are:

Age, Operating hours and Usage

Manufacturer history and reputation

Maintenance

Physical wear and tear

Performance in load test

Purchasing (broker or distributor)

Generator Age, Operating Hours and Usage:

The first thing you should pay attention to when buying a reliable used generator is the time clock, age and history of the generator set. Firstly, check what time the time clock is. It may also help to know what it is used for (prime/standby). A generator used as a standby or backup power source is better maintained and less worn than a generator used as a prime or continuous power source. However, keep in mind that age and usage information may not be available. Dealers often do not have detailed information about the origin and use of generators obtained from foreclosures or auctions. In such cases, the dealer’s reputation and technical expertise are important.

Manufacturer History and Reputation:

While the make and model are not always critical, the history and reputation of the generator manufacturer plays an important role in the used machine you choose. Do not rely on unrecognised brands as you will be purchasing a device that you can trust to meet your electrical energy (prime or standby). By choosing a reliable manufacturer, you can get a quality device as well as an advantage in terms of spare parts and warranty.

Maintenance

You may not be able to get detailed information about the past maintenance of the generator, but you can check the knowledge of the company you are buying from about maintenance, diesel engine repair, power units and transfer panels. You can question the seller’s current knowledge by asking simple questions about the procedures they use.

Physical Wear and Tear:

Visual Inspection

Your next step should be a visual inspection. A generator, like any mechanical device, may show wear during operation. Check all mechanical components for wear or malfunction. Check the mechanical parts for any cracks or corrosion. If any suspicious part is detected, it must be replaced with the parts recommended by the manufacturer.

Bearing and shaft housing replacement

Unless replaced by the dealer, all bearings and shaft housings must be replaced regardless of condition. Replacement will prevent any damage that may be caused by these parts during generator operation. Bearings and shaft bearings are under stress during generator operation, and it is very difficult to test these parts for any pressure they encounter while the generator is running. Therefore, from a safety point of view, it is best to replace these parts. The same applies to bolts and studs.

Wiring and solder integrity check

Check that the soldering parts are intact. Also check the electrical components and coils for integrity. Test the cable insulation for faults.

Load test

The load test is the most important standardised test that the vendor must have performed, enquire again to be sure. A load test helps to determine the overall efficiency of electrical power generation. The generator’s good response to varying loads is usually an indication of its efficiency within specified load limits. The type of electrical power produced by the generator indicates the overall condition of the generator set. The test should check for proper output and frequency. The test should be repeated three times to eliminate unexpected power failures.

Purchase (broker or dealer/distributor)

Industrial diesel generators are complex, finely tuned machines that must be tested by certified technicians to ensure that they operate correctly with optimum efficiency when you need them most. Since most diesel generators are highly priced, the reliability of the company from which they are purchased is important. Therefore, in order to eliminate risks, preference should be given to companies that have gained a certain industrial experience through years of service in this field.